hydro jetting machine checklist

If the water is properly pressurized this hydro jetting should clear most obstructions. Carry out the cleaning operation in full PPE in the enclosed area.

STOP the work if unsafe or potential hazardous condition found during the test.

. Use CALIBRATED pressure gauge for the test. Safe movement distances must also be monitored when the boom is in use. You could not unaided going taking into account book amassing or library or borrowing from your connections to admission them.

All electrical equipment required to support the - hydroblasting operations must be equipped to prevent electrocution eg grounded GFCI 32 Never use abrasive jetting in atmospheres above 10 LEL. Do not overfill the fuel tank there should be no fuel in the filler neck. Guidelines for Safe Operation and Maintenance.

The nozzle end is fed into the pipe and pressurized water is pumped through the hose to the nozzle which produces high-pressure water jets that remove debris as the nozzle moves down the pipe. Hydro jetting can take care of a broad range of materials. Heat Exchanger Tube Cleaning with Hydro jetting Machines.

31 All electrical equipment that may be impacted by hydroblasting including overspray must be covered deenergized or otherwise protected. After refueling make sure the tank cap is closed properly and securely. The supervisor responsible for the job will fill out the High-Pressure Water Cleaning Equipment Checklist form before starting each job.

PRESSUREJET manufactures High Pressure Hydro Jetting Machine for the pressures ranging from140 bar 2000 PSI to 1400 bar 20000 PSI This pressure range meet the tube cleaning requirements of most industrial applications. It cover pressure testing of new and existing pressure systems or components at a test pressure more than 0 psig. More than 1500 loyal customers and 5000 successful pumps installations worldwide.

COMMUNICATE the test planning prior to execution. The purpose of these checklist is to ensure that pressure tests are conducted safely and effectively. High pressure water jetting systems consist of an energy source like an electric motor or internal combustion engine a pump control mechanism hoses pipes nozzles and various other components necessary for the equipment to function as a system.

Additional 38 ¼ and 316 hoses can also be added to jet smaller pipes down to 1. When the hose is pressurized personnel must not handle the hose within one foot of the hose-to-hose connections. Hydro jetting solves such drain issues by pumping high-pressure water in the pipes.

The pressure must be removed from the system before tightening or loosening fittings. Heat Exchanger Tube Cleaning with Hydro jetting Machines. An ISO 90012015 certified company Manufacturing various applications pumps like Water Jet Cleaning Hydro Test Hydro Jetting Hydro Blasting Sewer Jetting Fire Fighting many more applications.

If there is only one operative the jetting gun should be placed at a safe distance with the nozzle facing away from the unit and operative or in the jetting gun holster if one is available. Common hazards and risks include the water jet piercing the skin being hit by flying debris. If a hot water unit was ordered.

Vertical Tube Cleaning with Water Jetting Systems. Tube cleaning - loose little hard scale and short length tubes. Do not smoke or allow flames or sparks in the area where the engine is refueled or where gasoline is stored.

John Holland Group Created Date. The jet works with gravity and forces the pipes to clear up. While its true that hydro jet equipment uses extreme pressure qualified technicians know how to use this equipment without damaging your pipes.

Get SAFETY WORK PERMIT prior to hydrotest. Neglected Grease Traps and Hydro Jetting. This sewer cleaning process uses highly pressurized water.

Safety practices must always be adhered to when overhead electrical lines and electrical equipment are present. It prevents and resolves plumbing backups. ABOUT Established in 1996 in Ahmedabad India.

Provides instructions on the use of the equipment both prior to and during operation. It apply to mechanics supervisors inspectors custodians and subcontractors responsible for pressure tests. Usually we conduct hydro jetting as a preventative measure when we service the grease traps in a commercial kitchen.

Zealand Standard ASNZS 42331 High Pressure Water Hydro Jetting Systems. The most popular jetting model the 4000PSI at 18GPM uses US Jettings brand of ½ high pressure hose rated for 16k burst pressure. When voltage is unknown it is required that all personnel and equipment on-site keep back a minimum of 7 meters from overhead lines.

Ensures workers recognise and manage associated hazards and risks involved. With most of the piping angling downward from your home into the sewer line the dislodged material causing the clogging will flow down into the sewer system. Equipment that does not comply with ASNZS 4233 will not be used.

Class a high pressure water jetting systems 800 5600 BAR LITRES PER MINUTE PLANT PRE-ACCEPTANCE CHECKLIST. This Waterjet Cutter Safe Operating Procedure SOP provides a way for your business to outline step-by-step safe processes when operating a Waterjet Cutter. A hydrojetting machine consists of a high-pressure hose line connected to a specialized jet nozzle on one end and a water pressure machine on the other.

Hydro jetting can shoot a maximum of 20 gallons of water per minute 5000 psi through your sewer pipes. But sometimes the grease trap have. This hose is specifically designed for longevity and durability while maintaining a high level of safety.

All high pressure water jetting equipment and actions will comply with AustralianNew. I have received and read the complete set of instructional and safety literature and shall use extreme care in the operation of the. The 2000 to 4000 PSI pressure breaks up and rids sewer drainage pipes of sludge grease mineral scale tree roots and other debris.

An indicator that you may need hydro jetting includes a smelly kitchen sink that repetitively clogs up. A plumber can help eradicate the obstructions in your pipes and allow you to live peacefully. CLASS A HIGH PRESSURE WATER JETTING SYSTEMS PLANT PRE-ACCEPTANCE CHECKLIST Last modified by.

As the operator I understand the potential and intent for the use and limits of the high pressure jetting equipment and high temperature of water generated by this equipment. It must be able to cover 15 to 2 times pressure test. Applications of Hydro Jetting MCs.

364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Pdf Valve Nozzle

Pdf Management Of Industrial High Pressure Fluid Injection Injuries Ihpfii The Water Jetting Association Wja Experience With Water Driven Injuries

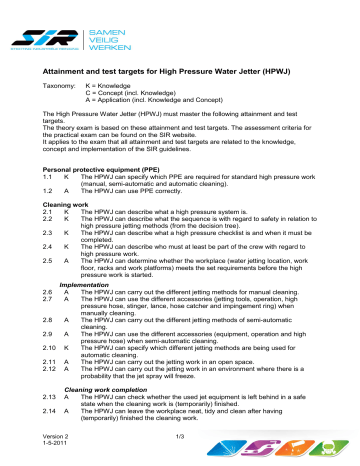

Attainment And Test Targets For High Pressure Water Jetter Hpwj Manualzz

Doc Identification Of Risk And Providing Guidance For Operation And Maintenance Gowtham Sundhar Academia Edu

364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Pdf Valve Nozzle

High Pressure Water Jetting Equipment Hydrojet Equipment Pressurejet

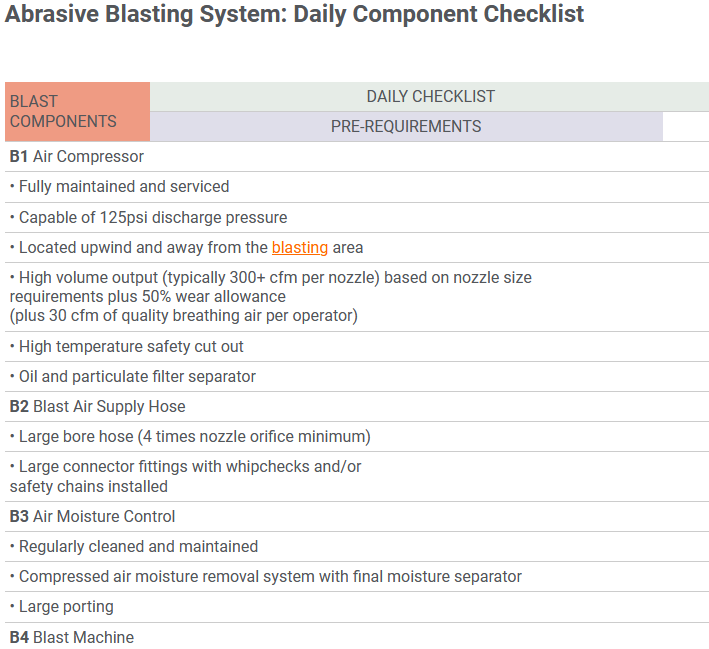

Abrasive Blasting System Daily Component Checklist Blast Booths Spray Paint Booths Abrasives Media And Equipment

364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Pdf Valve Nozzle

High Pressure Water Jetting Equipment Hydrojet Equipment Pressurejet

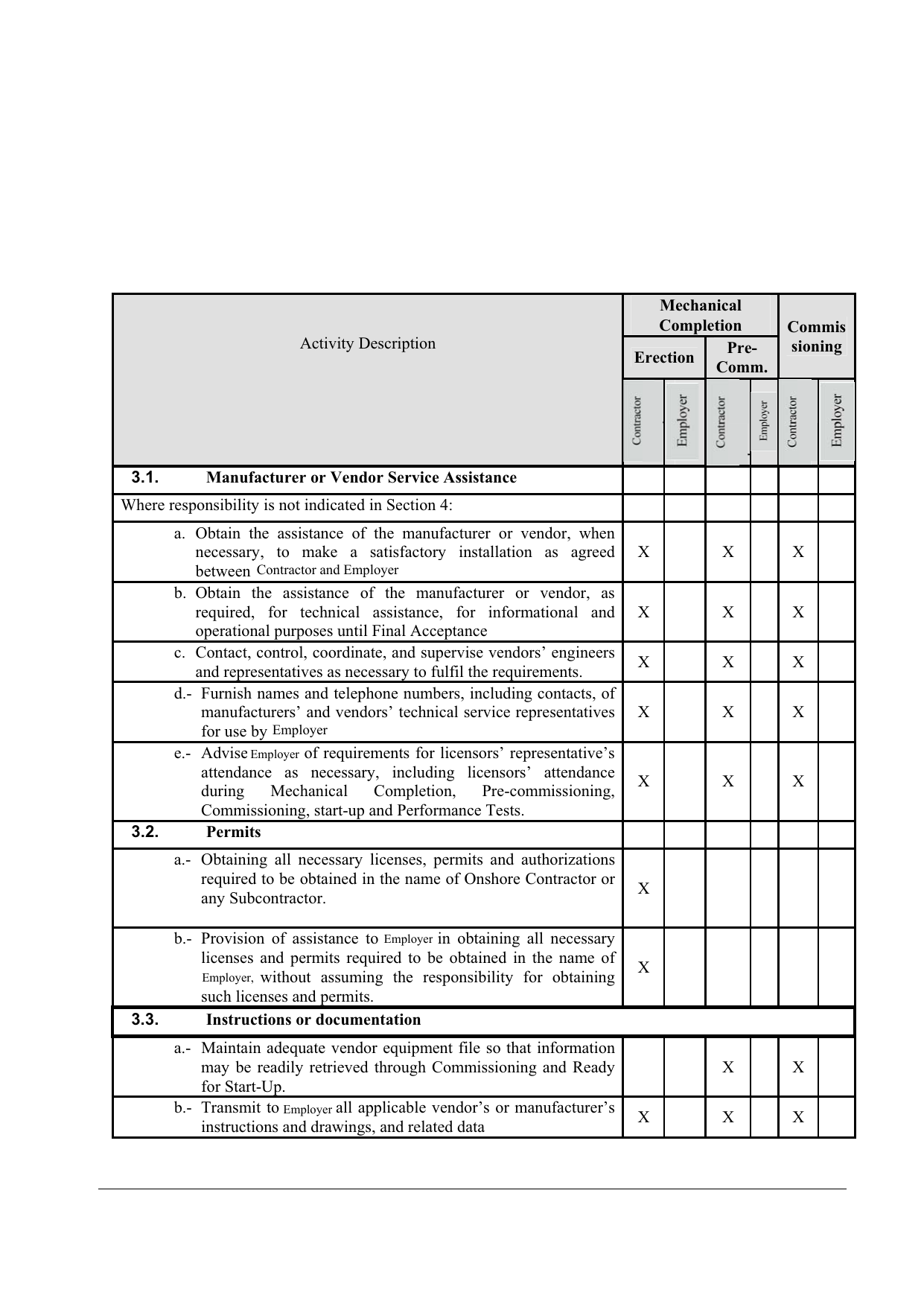

Exxi A R Epc Schedule 10 Mechanical Completion Checklist Execution Version 3

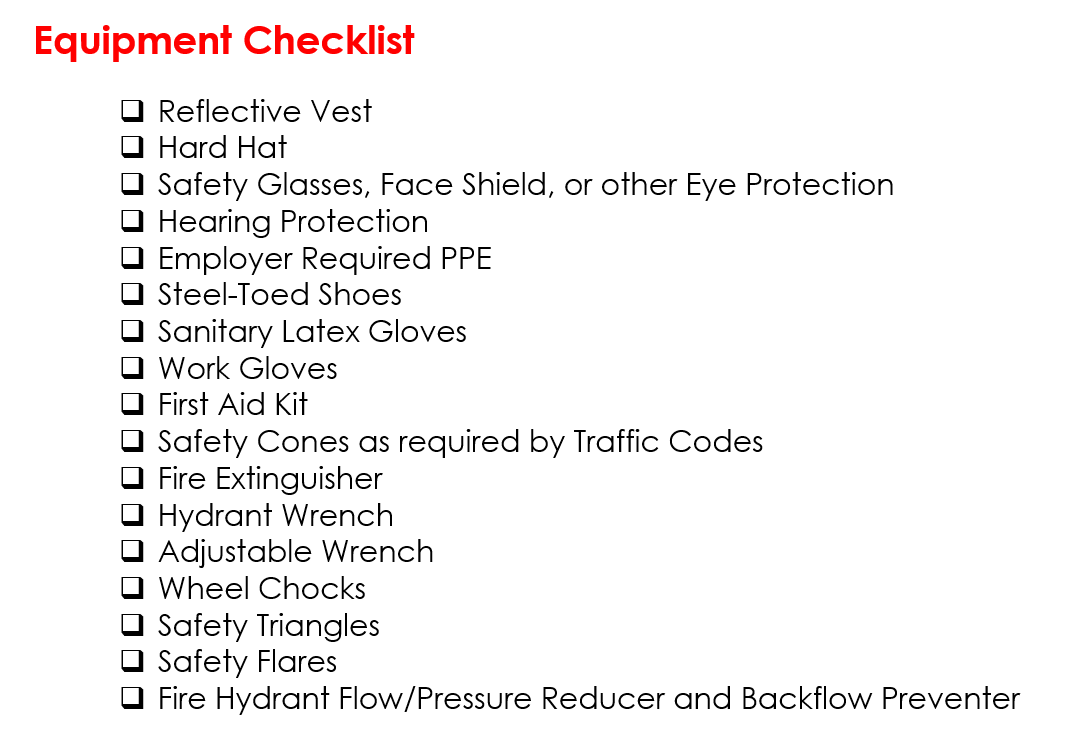

Pre Operation Checklist Safetyculture

Residential And Commercial High Pressure Sewer Jetting Hb Mcclure

Essential Equipment For Essential Operations Vac Con

Jsa Hydro Jetting Pdf Personal Protective Equipment Safety

Sump Pump Facts Atlanta Plumbers Clog Dawg Plumbing Hydrojetting